Maintenance Of Drip Irrigation System to Improve Agriculture Crop Yield

Drip Irrigation Technology

Drip irrigation is a technology that requires perfection in Hydraulic design, Agronomic knowledge, and overall experts in Precision Agriculture. Netafim an Orbia group of company is working for the last 58 years to serve the farming community to Grow More with less.

Drip Irrigation not only saves water, Fertilizer, Labour, and Fertilizer, Power but also increases the quality & yield of Crops. Drip irrigation can be said to be successful only when a Precision amount of Water & Fertilizer can be applied at the Root zoon of the crop.

Proper & correct farm inputs (FSQ) i.e., farm survey questionnaire regarding availability of water, water quality, soil type, soil, available Pump HP, Energy source, Crop spacing & type of system (Drip/Mini) to be used important to design a proper drip system & get it installed. Tools used for installations should be as per company recommendations i.e., Drill bit, Dripper Punch, Spanner sets, etc.

The benefits of Micro irrigation can be availed only if the system performs as per design a proper maintenance is carried out. Maintenance of the System is important to increase the life of the Drip System & increase ROI & System Performance resulting in cost savings & higher profits for Farmers.

As per Government of India Guidelines for BIS-marked Drip systems, it is mandatory to provide Maintenance Manual & training to farmers regarding the installation & maintenance of Drip Irrigation Systems in vernacular language.

Farmers must be made aware of the function & Maintenance of each part of the MIS system. We, Netafim, through our authorized dealers, technical staff & Company technicians/Engineers help to guide farmers by providing after-sales technical services (ASTS). It is the prime duty of farmers to follow instructions given by technical representatives of the Dealer/Company regarding installations & Maintenance.

Importance of Maintenance & Types of Maintenance

Preventive maintenance: It is carried out to avoid /reduce Future maintenance & to increase system life.

- Installation of the System should be done as per Design.

- Soil & Water Testing- It helps to decide the type of impurities & Quality.

- Back Flushing of Gravel Filter, Cleaning of Hydro cyclone Filter, Disc/Screen Filters.

- Flushing of laterals & Driplines.

- Flushing of Main & sub main Lines.

Corrective Maintenance: This is carried out after diagnosis of low performance of the system.

- Acid Treatment/Chlorine Treatment.

- Repair leakages.

- Maintenance of consumable parts.

Important Terminology & its Effect in Drip Irrigation:

Pump Performance:

It is to be assured by a farmer that the head & discharge of the Pump should be as per Design.

- Check the Foot valve.

- Suction Pipe leakages

- Impeller rusting (Wear & tear)

- Rubber parts etc.

- Electric Parts /starter /stabilizers/Relays etc.

Head Unit & Safety Equipment:

The head unit is the heart of the system that removes Physical & biological impurities from water. Water is delivered through the small orifice of the Dripper /Dripline/Nozzle. Impurities, so it is important to have a proper filtration system.

- Water quality decides the Filtration System to be used.

- Filters should be cleaned based on the Water Quality & Pressure difference of the inlet & outlet of the Filters.

- The proper Platform of the Filter enables easy operations of the Head unit.

- Farmers should use safety equipment like Air release valves, Bypass valves, Pressure relief valves, non-return valves, PSV, etc as per design recommendations, which will help to save the drip system.

Pressure:

Drip irrigation is a Pressurized irrigation system. The normal Operating pressure is 1 kg.cm2 at the lateral end) The Farmer needs to check pressure at various points mentioned below.

i) Inlet & outlet of Ventury /Fertiliser tank, Inlet & Outlet of Primary & Secondary Filter of Head Unit)

ii) Inlet of Submain & at submain Flush valve.

iii) Inlet & Outlet of Laterals/driplines

iv) Inlet Of Drippers.

This will help to decide the health of the system regularly.

Any variation in the inlet-outlet of Filters will guide farmers to back flush or clean the filters. Every farmer should have Pressure a gauge with a bob cock & adopter /needle to measure pressure at various points.

Flushing of Laterals, Flush valves: -

- Farmers need to Flush laterals/Driplines regularly. (Every 15 days)

- Submain Flush valves should be opened & cleaned until clean water comes out (Once a week)

Acid/ Chlorine Treatment

- If clogging of Drippers & Discharge variation is found, It is necessary to go for acid treatment or Chlorine as per process by using all safety measures & under supervision.

- It is to ensure that all systems should be flushed before & after this treatment.

Pre & Post Season

- Framer should clean laterals by acid treatment or flush laterals driplines after the crop cycle is over & then wind it by using winders.

- Driplines should be stored properly & Plotwise /Discharge-wise to avoid Mixing.

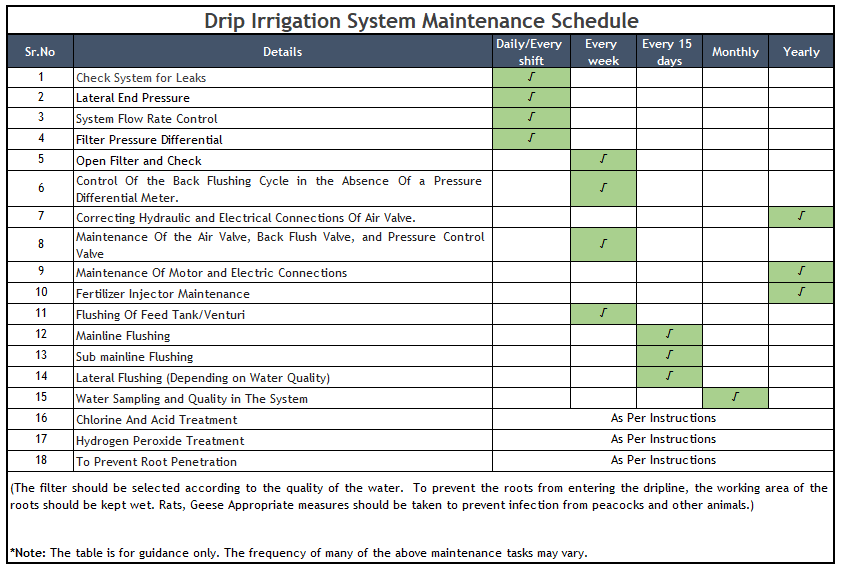

The Maintenance Schedule/Calendar:

If you have any further Queries/Questions Please do contact for more details:

To Contact: https://www.netafimindia.com/contact-us/

Visit our website: https://www.netafimindia.com/

Toll-free Number: 1800 103 5000

COMMENTS

We'd love to hear your thoughts! To enter a comment, type your name and email address.